In today's rapidly advancing industrial landscape, effective sludge management is paramount. The three-tube charcoal block paddle blade sludge rotary drying equipment stands at the forefront of this technology, offering innovative solutions for efficient sludge processing. This article delves into the design, functionality, and benefits of this advanced machinery.

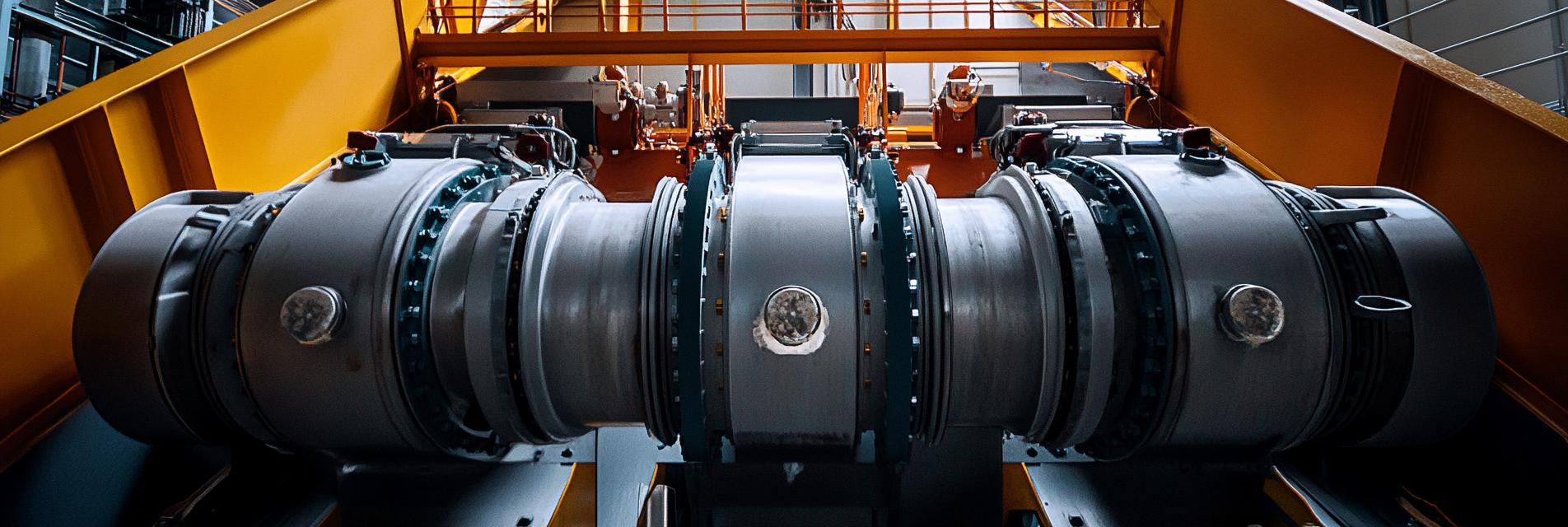

The three-tube design of this equipment ensures maximum heat exchange efficiency, facilitating faster drying times compared to traditional methods. The paddle blade system operates dynamically, allowing for uniform sludge turnover and preventing clumping, which enhances the overall drying process.

Incorporating cutting-edge technology, the sludge rotary dryer adjusts temperatures and airflow conditions automatically to optimize drying effectiveness. This adaptability not only conserves energy but also extends the longevity of the equipment. By utilizing charcoal blocks, this system provides a sustainable approach to sludge drying, efficiently transforming waste into usable products.

By employing this innovative sludge drying solution, industries can significantly reduce their environmental impact. The rotary drying process eliminates excess moisture, decreases disposal costs, and enhances the overall sustainability of waste management practices.

The three-tube charcoal block paddle blade sludge rotary drying equipment represents a significant advancement in sludge processing technology. Its efficient design, advanced features, and environmental benefits mark it as a crucial tool for industries aiming to improve their waste management practices. Investing in such equipment not only enhances operation efficiency but also contributes to a cleaner and more sustainable industrial future.